Understanding Charcoal Briquettes and the Manufacturing Process

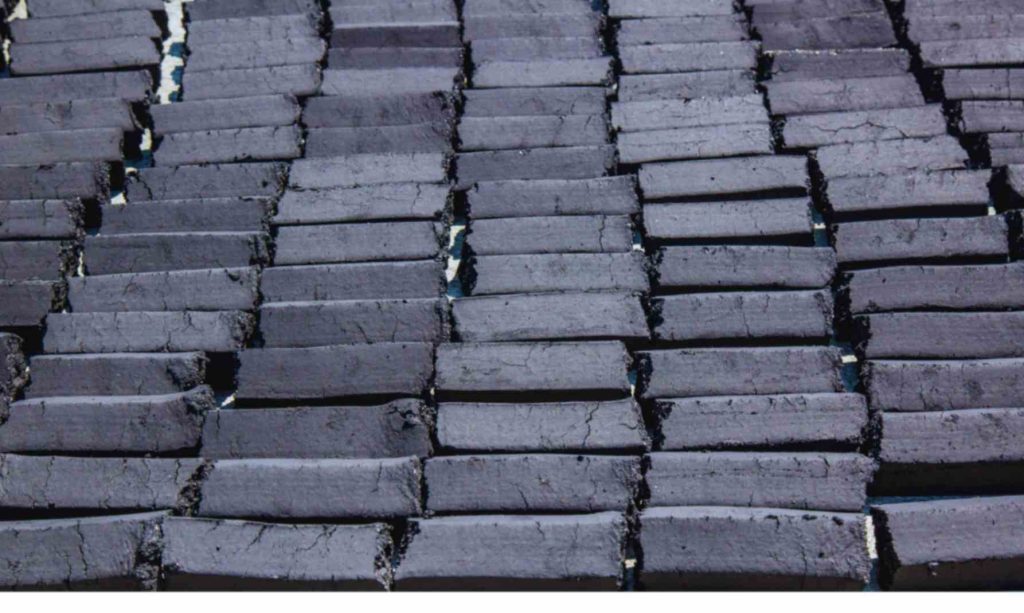

Briquette charcoal is a fuel produced from the carbonization process of organic materials, such as sawdust, agricultural waste, and other biomass materials. The process of making briquette charcoal involves drying, grinding, and molding the raw materials into solid briquettes. In industry, briquette charcoal has been shown to significantly improve energy efficiency. With stable combustion characteristics and high heat, briquette charcoal can replace fossil fuels in many industrial applications. One of the main benefits of briquette charcoal in industry is its ability to reduce carbon emissions. When compared to conventional fuels, briquette charcoal produces significantly lower greenhouse gas emissions, helping industries meet increasingly stringent environmental standards.

Advantages of Charcoal Briquettes Compared to Other Fuels

One of the main advantages of briquette charcoal is its environmentally friendly nature. The use of briquette charcoal in industrial processes not only helps reduce carbon emissions but also reduces dependence on increasingly scarce fossil fuels. In addition, lower operating costs compared to other fuels are a special attraction for industrial players. Briquette charcoal is not only cheaper in terms of price per unit of energy but also has a longer service life and better combustion efficiency. Thus, industries that switch to briquette charcoal can enjoy significant cost savings while contributing to environmental conservation.

Positive Impact of Using Charcoal Briquettes on the Environment

The use of briquette charcoal in industrial processes has significant positive impacts on the environment. One of the main impacts is the reduction of carbon emissions produced during industrial processes. This is crucial in the global effort to reduce climate change and its negative impacts. In addition, briquette charcoal also increases energy efficiency in industrial production. With cleaner and more efficient combustion, industries can reduce their overall energy consumption, which in turn reduces their carbon footprint. These positive impacts make briquette charcoal a very attractive alternative for industries concerned with sustainability and environmental responsibility.

Application of Charcoal Briquettes in Various Industrial Sectors

Briquette charcoal has wide applications in various industrial sectors, especially in the food processing industry. In the food processing process, briquette charcoal can be used as a heat source for cooking and processing products. One of the benefits of briquette charcoal in this industry is its ability to increase energy efficiency. With more efficient combustion, the industry not only saves energy but also produces higher quality products. In addition, the use of briquette charcoal in the food processing industry can improve the company’s image as an environmentally friendly industry player, which is increasingly sought after by consumers today.

Strategy to Increase Energy Efficiency Using Charcoal Briquettes

In an effort to improve energy efficiency, the use of charcoal briquettes can be a very effective strategy. Charcoal briquettes not only reduce greenhouse gas emissions, but also increase productivity with lower energy costs. By switching to charcoal briquettes, companies can reduce their operational costs while still meeting their energy needs. This not only creates financial benefits, but also makes a positive contribution to the environment. In the context of an increasingly competitive industry, this strategy becomes even more relevant, as companies that adopt sustainable practices will have a greater competitive advantage in the market.

With all the benefits it offers, it is clear that charcoal briquettes are a smart and sustainable solution to improve efficiency in the industry.